Products

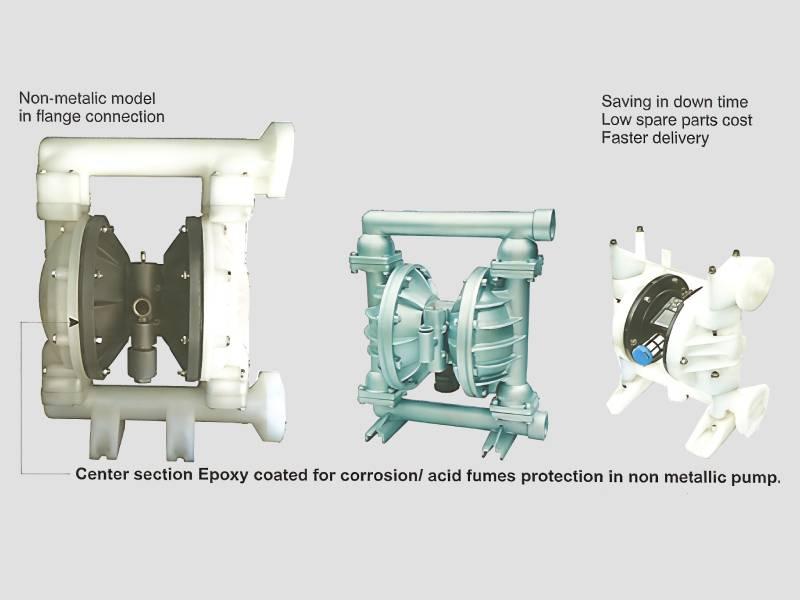

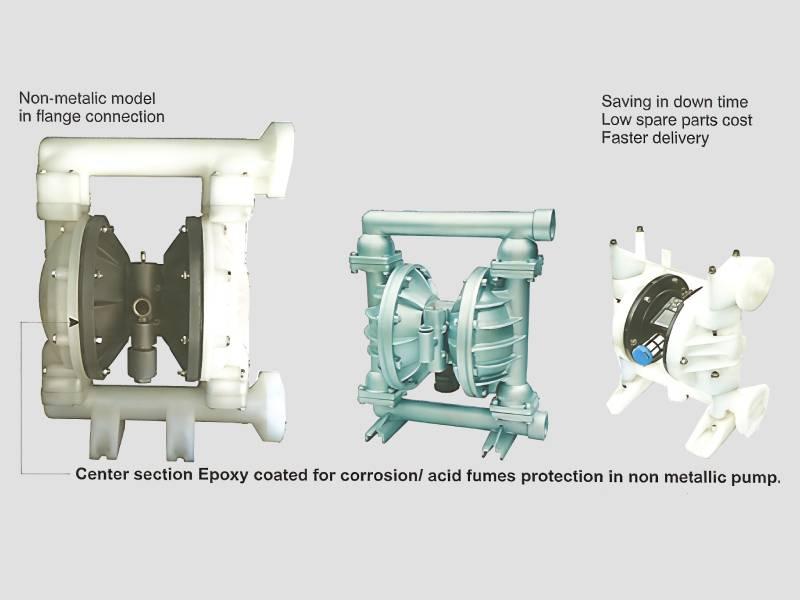

Air Driven Dual Diaphragm Pumps are engineered for efficient chemical transfer in industrial applications. The pump uses compressed air to drive two flexible diaphragms alternately. This design allows smooth fluid movement without direct mechanical seals. It is suitable for handling corrosive, viscous, and shear sensitive chemicals. The pump can run dry without damage, ensuring operational safety. Robust construction supports continuous industrial usage. Flow rate adjusts easily by controlling air supply pressure. Maintenance is simplified due to fewer moving parts. The pump offers safe operation in hazardous and explosive areas. Installation is flexible with portable or fixed mounting options. Custom material configurations are available based on chemical compatibility.

Cheque,NEFT And RTGS

Key Attributes

Industry-specific Attributes

- Pump Type Air driven dual diaphragm pump

- Power Source Compressed air

- Fluid Handling Chemical and corrosive liquids

- Operation Safety Explosion proof design

- Seal Design Seal less diaphragm system

- Flow Control Air pressure regulated

- Mounting Style Portable or fixed installation

- Maintenance Level Low due to simple mechanism

Other Attributes

- Chemical Compatibility Material dependent configuration

- Viscosity Handling Suitable for thick fluids

- Priming Capability Self priming operation

- Dry Run Tolerance Yes

- Installation Flexibility Multiple orientation support

- Customization Scope Diaphragm and body material options

- End User Segment Chemical transfer industry operators

Stainless Steel 316 CF8M End Suction Units are engineered for demanding process plant applications. The pump casing is manufactured from CF8M stainless steel, equivalent to SS 316 grade. This material provides superior resistance to corrosion and chemical attack. The end suction design allows simple installation and easy maintenance. The pump delivers smooth and stable fluid flow for process requirements. It is suitable for handling clean and mildly corrosive liquids. Robust construction supports continuous duty operation. Shaft sealing arrangement ensures leak controlled performance. The pump operates efficiently across a wide operating range. Noise and vibration levels are controlled for plant environments. Custom configurations are available based on capacity and process conditions.

Cheque,NEFT And RTGS

Key Attributes

Industry-specific Attributes

- Pump Type End suction centrifugal pump

- Material Grade Stainless steel 316 CF8M

- Process Fluid Clean and mildly corrosive liquids

- Operational Duty Continuous plant operation

- Suction Orientation End suction configuration

- Discharge Direction Radial outlet

- Corrosion Protection Stainless steel construction

- Efficiency Focus Stable hydraulic design

Other Attributes

- Maintenance Access Easy service layout

- Installation Style Base plate or inline mounting

- Seal Arrangement Mechanical seal compatible

- Noise Level Controlled industrial operation

- Customization Scope Flow and head specific

- Reliability Level Long term process performance

- End User Segment Industrial process plant operators

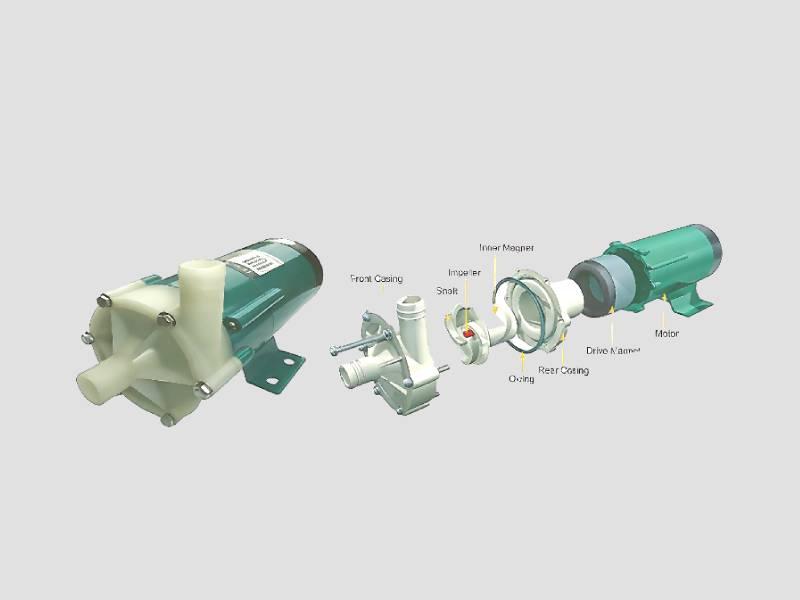

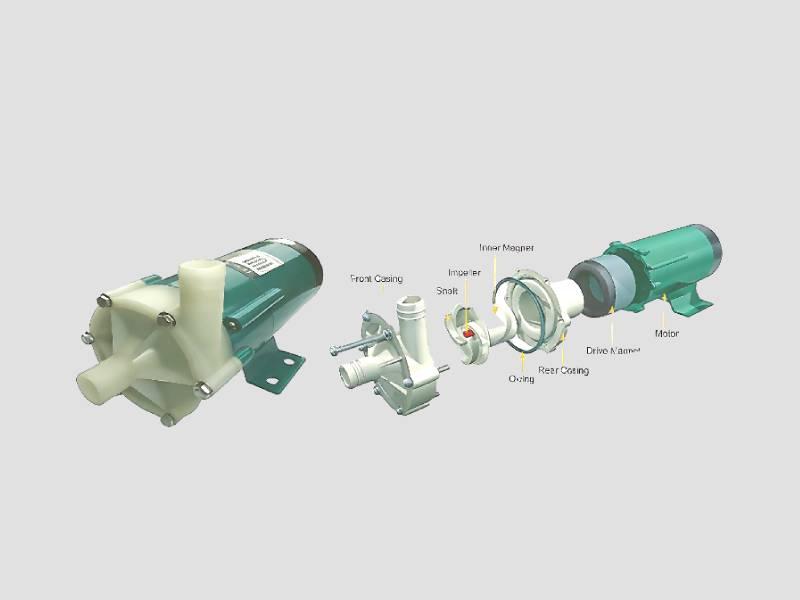

Magnetic Coupled Leak Proof Flow Systems are engineered for handling hazardous and toxic fluids safely. The pump uses a magnetic coupling to transmit torque without direct mechanical contact. This eliminates the need for conventional shaft seals. The sealless design prevents leakage and environmental contamination. It is ideal for aggressive, flammable, and toxic liquids. Robust construction supports continuous industrial operation. Heat generation is minimized through efficient magnetic alignment. The system offers stable flow with minimal vibration. Maintenance requirements are reduced due to the absence of dynamic seals. Installation is suitable for compact process layouts. Custom designs are available based on fluid properties and operating conditions.

Cheque,NEFT And RTGS

Key Attributes

Industry-specific Attributes

- System Type Magnetic coupled flow system

- Drive Method Magnetic torque transmission

- Leakage Risk Zero leakage design

- Fluid Type Hazardous and toxic liquids

- Seal Arrangement Sealless configuration

- Operational Safety High containment pumping

- Maintenance Requirement Minimal seal related service

- Installation Style Compact skid or inline mounting

Other Attributes

- Temperature Handling Process dependent design

- Pressure Capability Industrial rated operation

- Material Options Metal or lined construction

- Energy Efficiency Reduced mechanical losses

- Noise Level Low operational noise

- Customization Scope Fluid compatibility specific

- End User Segment Hazardous fluid handling industries

Polypropylene and PVDF Construction Liquid Handling Equipment is engineered for handling corrosive and aggressive liquids. The non metallic body eliminates rust and chemical attack risks. Polypropylene construction suits general chemical applications. PVDF material is ideal for highly aggressive chemicals and high purity processes. The equipment ensures reliable fluid transfer in demanding environments. Lightweight construction simplifies installation and handling. Smooth internal surfaces reduce chemical buildup and contamination. The system supports continuous industrial operation. Maintenance requirements are minimal due to corrosion resistant materials. The design ensures safe operation without metal contamination. Custom material selection is available based on chemical compatibility.

Cheque,NEFT And RTGS

Key Attributes

Industry-specific Attributes

- Equipment Type Non metallic liquid handling system

- Construction Material Polypropylene or PVDF

- Chemical Resistance Excellent against acids and alkalis

- Operational Duty Continuous industrial use

- Weight Advantage Lightweight compared to metal units

- Contamination Risk Non reactive material design

- Installation Style Skid or inline mounting

- Maintenance Level Minimal corrosion related service

Other Attributes

- Fluid Compatibility Aggressive chemical liquids

- Temperature Suitability Material dependent range

- Pressure Handling Industrial chemical rated

- Surface Finish Smooth internal passages

- Energy Efficiency Low friction flow path

- Customization Scope Material and configuration specific

- End User Segment Chemical process and treatment industries

_209681.jpg)

PVDF and PFA Fluoropolymer Lined Corrosion Resistant Flow Units are engineered for aggressive chemical environments. The internal fluoropolymer lining protects metal components from corrosion. PVDF lining is suitable for a wide range of industrial chemicals. PFA lining offers superior resistance for highly aggressive and high purity applications. The unit ensures reliable flow with long service life. Smooth lined surfaces reduce friction and product contamination. Robust outer casing provides mechanical strength. The system supports continuous industrial operation. Maintenance requirements are minimized due to lining protection. The design ensures safe handling of hazardous fluids. Custom lining and configuration options are available based on process needs.

Cheque,NEFT And RTGS

Key Attributes

Industry-specific Attributes

- Unit Type Fluoropolymer lined flow unit

- Lining Material PVDF or PFA

- Base Structure Metallic housing with lining

- Corrosion Protection High chemical resistance

- Operational Duty Continuous industrial service

- Fluid Type Aggressive and hazardous chemicals

- Surface Characteristic Smooth lined interior

- Maintenance Requirement Reduced due to lining

Other Attributes

- Installation Style Inline or skid mounted

- Pressure Capability Industrial chemical rated

- Temperature Handling Lining dependent suitability

- Safety Level Leak controlled chemical transfer

- Customization Scope Lining thickness and material

- Reliability Level Long term corrosion protection

- End User Segment Corrosive chemical handling industries

_209681.jpg)

Self Priming Stainless Steel Liquid Circulation Solutions are engineered for utility and industrial circulation applications. The self priming design enables the pump to evacuate air and start automatically. Stainless steel construction provides strength and resistance to corrosion. The system delivers continuous and stable liquid circulation. It is suitable for handling clean and mildly corrosive liquids. Compact design allows easy installation in utility lines. The solution supports frequent start stop operations. Maintenance is simplified due to accessible construction. Energy efficiency is maintained during continuous operation. Noise and vibration are controlled for utility environments. Custom configurations are available based on flow and circulation requirements.

Cheque,NEFT And RTGS

Key Attributes

Industry-specific Attributes

- Solution Type Self priming circulation system

- Construction Material Stainless steel

- Priming Method Automatic self priming

- Primary Function Liquid circulation

- Operational Duty Continuous utility operation

- Fluid Type Clean and mildly corrosive liquids

- Installation Style Inline or base mounted

- Maintenance Level Low routine service

Other Attributes

- Energy Efficiency Optimized circulation design

- Noise Level Controlled utility operation

- Startup Capability Fast without manual priming

- System Integration Utility piping compatible

- Customization Scope Flow and installation specific

- Reliability Level Stable long term circulation

- End User Segment Utility and service system operators

_209681.jpg)

CHM Grade Stainless Steel 316 Horizontal Flow Machines are designed for demanding industrial operations. The use of CHM grade SS 316 provides excellent resistance to chemicals and corrosion. Horizontal flow configuration ensures steady and controlled fluid movement. The machine supports continuous duty operation with consistent output. It is suitable for clean, treated, and mildly aggressive industrial fluids. Strong structural design enhances reliability and service life. Compact horizontal layout simplifies plant integration. Maintenance activities are easier due to accessible construction. The system performs efficiently under varying process loads. Noise and vibration levels are maintained within industrial limits. Custom designs are available to suit specific process flow and industry requirements.

Cheque,NEFT And RTGS

Key Attributes

Industry-specific Attributes

- Machine Type Horizontal flow industrial machine

- Material Specification CHM grade stainless steel 316

- Process Orientation Horizontal flow path

- Operational Mode Continuous process operation

- Fluid Handling Nature Clean and mildly corrosive fluids

- Corrosion Resistance Level Industrial grade SS protection

- Installation Method Inline or base frame mounting

- Maintenance Design Easy access service points

Other Attributes

- Performance Stability Consistent flow delivery

- Noise Control Industrial acceptable limits

- Vibration Management Balanced mechanical structure

- Customization Scope Process flow and layout specific

- Reliability Index Long term industrial performance

- System Integration Compatible with process pipelines

- End User Segment Industrial process and manufacturing units