Products

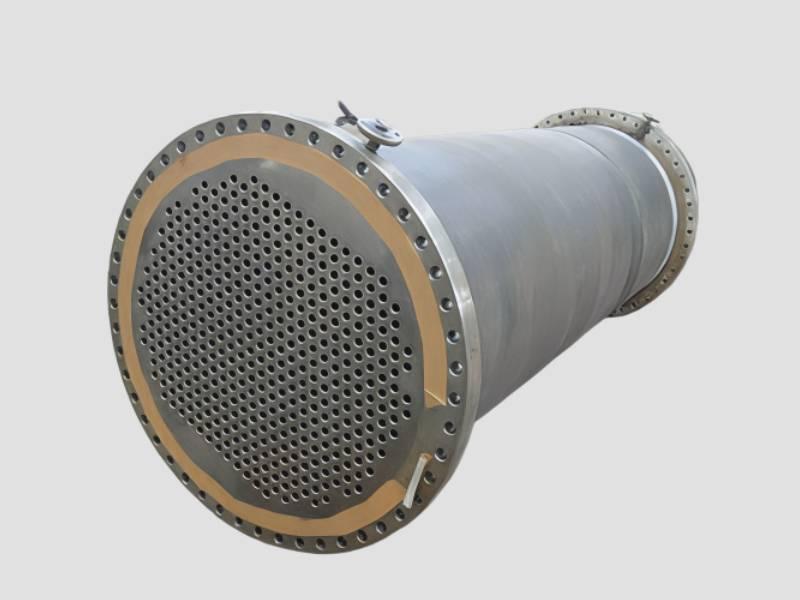

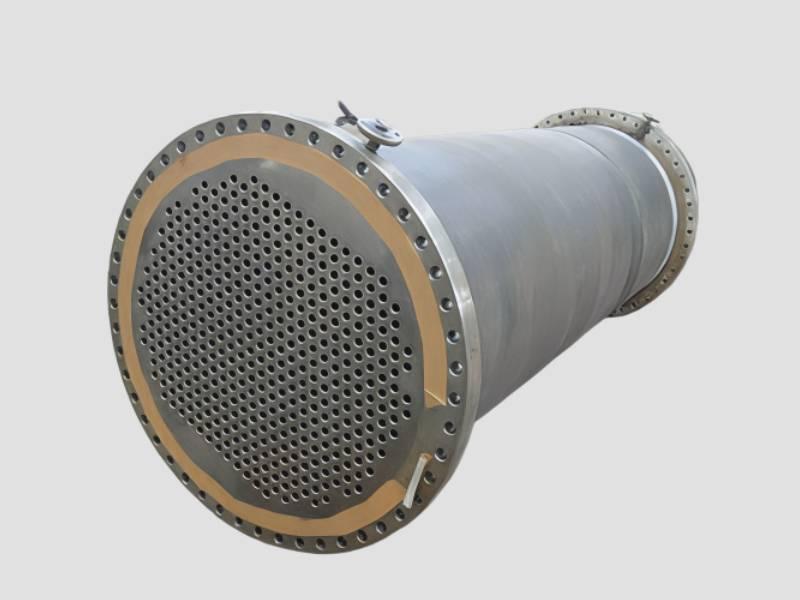

Shell and Tube Heat Exchangers are engineered to handle high pressure fluids in industrial cooling applications. The design allows efficient heat transfer between a hot process fluid and a cooling medium. Tubes are arranged to maximize surface area and thermal efficiency. The unit supports stable temperature control even under variable flow rates. Heavy duty construction ensures long term reliability in high pressure conditions. Maintenance access is designed for tube cleaning and inspection. Energy efficiency is achieved through optimized flow distribution and heat transfer design. Integration with existing process piping is straightforward. Noise and vibration are minimized through robust structural design. The system is suitable for chemical, petrochemical, and manufacturing industries. Custom configurations are available based on pressure ratings, flow capacity, and process requirements.

Cheque,NEFT And RTGS

Key Attributes

Industry-specific Attributes

- Heat Exchanger Type Shell and tube

- Pressure Rating High pressure industrial use

- Cooling Medium Water or process fluid

- System Design Heavy duty industrial construction

- Operational Duty Continuous high pressure operation

- Energy Efficiency Optimized heat transfer

- Temperature Control Stable process cooling

- Maintenance Approach Tube cleaning and inspection access

Other Attributes

- Installation Type Skid or floor mounted

- Integration Capability Process piping compatible

- Flow Capacity Customizable based on application

- Noise Level Minimized through design

- Customization Scope Pressure, flow, and fluid specific

- Reliability Level Industrial grade performance

- End User Segment High pressure industrial process operators

Industrial Radiators are engineered to dissipate heat from liquids in industrial cooling applications. The radiator transfers thermal energy from the hot fluid to ambient air using high surface area fins. They are suitable for hydraulic oil, water, and other process fluid cooling. Robust construction ensures long term reliability under continuous duty. Compact and modular design allows easy integration with existing systems. Cooling performance remains stable under varying fluid flow and ambient conditions. Maintenance is simplified with accessible fin and core assemblies. Energy efficient design reduces operational costs. Noise and vibration are minimized for industrial environments. The system is applicable across multiple industrial sectors. Custom configurations are available to meet specific fluid flow and thermal dissipation requirements.

Cheque,NEFT And RTGS

Key Attributes

Industry-specific Attributes

- Equipment Type Industrial radiator

- Cooling Medium Water, hydraulic oil, or process fluid

- Heat Dissipation Method Liquid to air

- Operational Duty Continuous industrial use

- Material Corrosion resistant metal construction

- Temperature Control Stable fluid temperature maintenance

- Energy Efficiency Optimized thermal performance

- Installation Type Floor or skid mounted

Other Attributes

- Maintenance Focus Accessible fin and core assemblies

- Noise Level Low operational sound

- Integration Capability Process piping compatible

- Customization Scope Fluid type, flow rate, and heat load

- Cooling Stability Consistent performance under varying conditions

- Reliability Level Industrial grade performance

- End User Segment Industrial process cooling operators

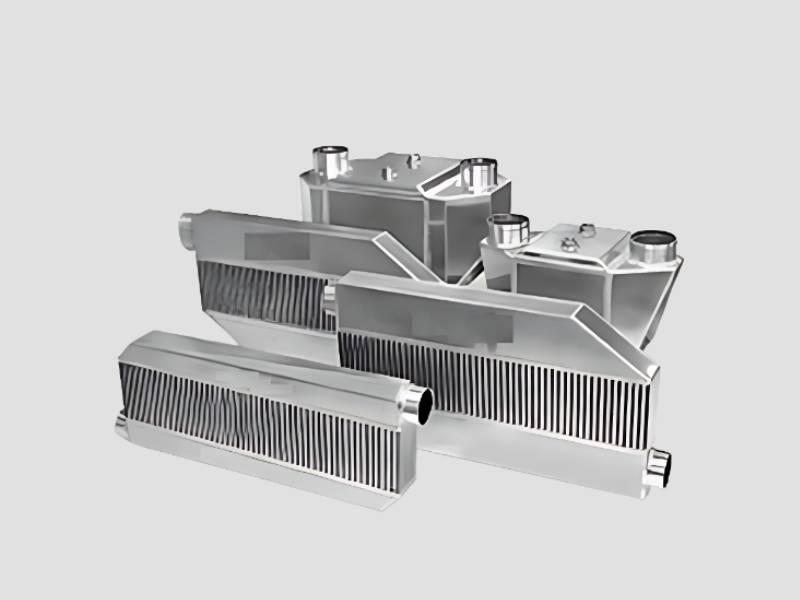

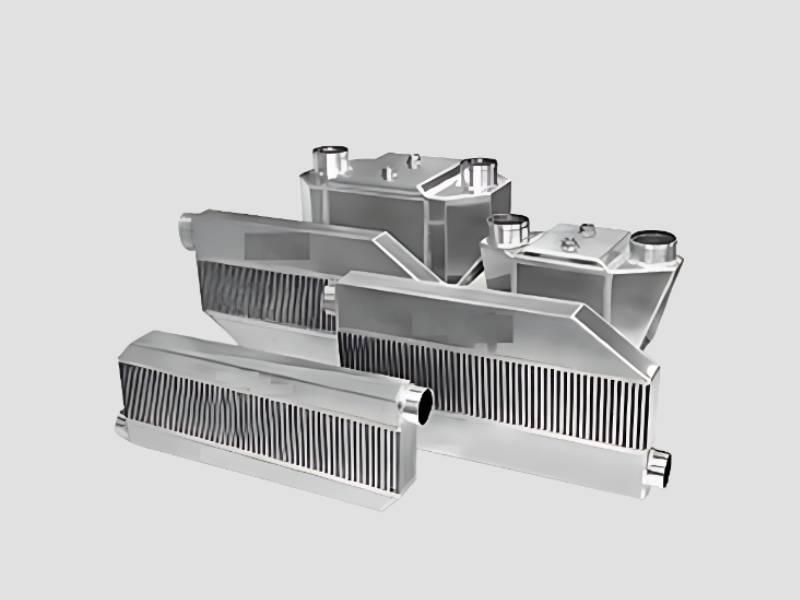

Intercooler Heat Exchangers are engineered to remove heat from compressed air in industrial applications. By reducing the temperature of compressed air between stages, they increase the efficiency of compressors. The system supports stable air output and improves downstream process reliability. Heavy duty construction ensures long term operation in demanding industrial environments. Compact design allows integration with existing compressor setups. Maintenance access is designed for easy cleaning and inspection. Energy efficient operation reduces operational costs. Noise and vibration levels are minimized through optimized airflow and structural design. The intercooler integrates seamlessly with industrial compressed air piping systems. Cooling performance remains consistent under variable pressure and flow conditions. Custom configurations are available to meet specific pressure, airflow, and temperature requirements.

Cheque,NEFT And RTGS

Key Attributes

Industry-specific Attributes

- Equipment Type Intercooler heat exchanger

- Cooling Medium Compressed air

- Operational Duty Continuous industrial use

- Heat Transfer Method Air to air or air to water

- Installation Style Inline with compressor stages

- Energy Efficiency Optimized for industrial air systems

- Cooling Stability Consistent air temperature control

- Maintenance Focus Easy inspection and cleaning

Other Attributes

- Noise Level Low operational sound

- Integration Capability Industrial compressed air piping

- Customization Scope Pressure, airflow, and temperature specific

- Reliability Level Heavy duty industrial performance

- Material Corrosion resistant construction

- System Compatibility Compatible with multi-stage compressors

- End User Segment Industrial air compression and process systems

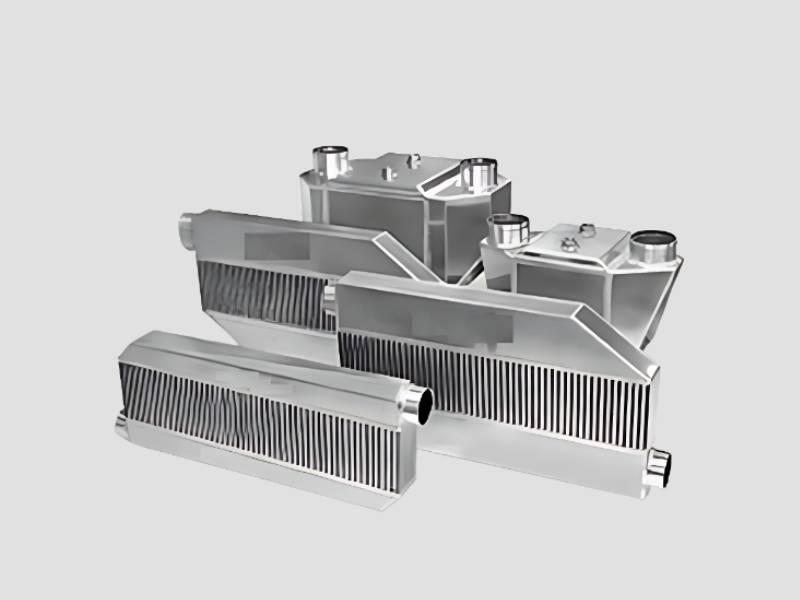

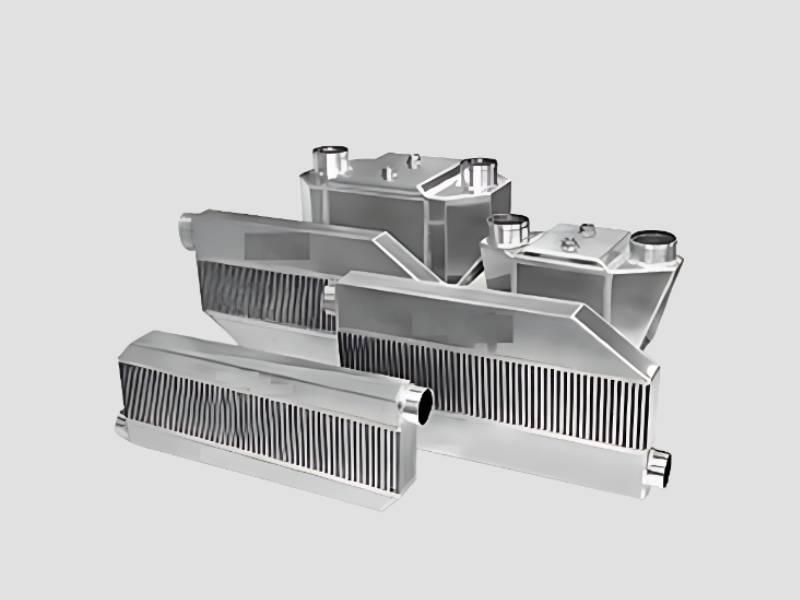

Intercooler Heat Exchangers are engineered to remove heat from compressed air in industrial applications. By reducing the temperature of compressed air between stages, they increase the efficiency of compressors. The system supports stable air output and improves downstream process reliability. Heavy duty construction ensures long term operation in demanding industrial environments. Compact design allows integration with existing compressor setups. Maintenance access is designed for easy cleaning and inspection. Energy efficient operation reduces operational costs. Noise and vibration levels are minimized through optimized airflow and structural design. The intercooler integrates seamlessly with industrial compressed air piping systems. Cooling performance remains consistent under variable pressure and flow conditions. Custom configurations are available to meet specific pressure, airflow, and temperature requirements.

Cheque,NEFT And RTGS

Key Attributes

Industry-specific Attributes

- Equipment Type Intercooler heat exchanger

- Cooling Medium Compressed air

- Operational Duty Continuous industrial use

- Heat Transfer Method Air to air or air to water

- Installation Style Inline with compressor stages

- Energy Efficiency Optimized for industrial air systems

- Cooling Stability Consistent air temperature control

- Maintenance Focus Easy inspection and cleaning

Other Attributes

- Noise Level Low operational sound

- Integration Capability Industrial compressed air piping

- Customization Scope Pressure, airflow, and temperature specific

- Reliability Level Heavy duty industrial performance

- Material Corrosion resistant construction

- System Compatibility Compatible with multi-stage compressors

- End User Segment Industrial air compression and process systems

Tube Bundle Replacement Assemblies are engineered for use in industrial process heat exchangers. They restore optimal thermal performance by replacing old or damaged tubes. The assemblies are manufactured to precise specifications to ensure proper fit and function. High quality materials ensure corrosion resistance and long-term durability. Installation is designed to be straightforward for industrial maintenance teams. Using replacement tube bundles helps maintain stable process temperatures. The system supports continuous operation of heat exchangers without significant downtime. Compatibility with various industrial heat exchanger models ensures broad applicability. Maintenance access is simplified for quick replacement and inspection. Energy efficiency is preserved by maintaining effective heat transfer. Custom tube bundle assemblies can be provided to match specific process requirements.

Cheque,NEFT And RTGS

Key Attributes

Industry-specific Attributes

- Component Type Tube bundle replacement assembly

- Material Corrosion resistant metal alloys

- Process Compatibility Industrial heat exchangers

- Operational Duty Continuous industrial use

- Installation Approach Replaceable assembly

- Thermal Efficiency Maintains optimal heat transfer

- Maintenance Focus Easy replacement and inspection

- Customization Scope Tube size, material, and count

Other Attributes

- Integration Capability Fits existing heat exchanger units

- Durability Level Heavy duty industrial performance

- Energy Efficiency Preserves original system efficiency

- Temperature Rating High temperature process compatible

- Pressure Rating Industrial process standards

- System Reliability Ensures stable operation post replacement

- End User Segment Industrial process heat exchanger operators

ALU Heat Exchangers are engineered using high quality aluminum for industrial thermal transfer applications. The lightweight construction reduces installation weight without compromising structural integrity. The design provides efficient heat transfer for process fluids and cooling media. Corrosion resistant aluminum ensures long-term durability in various industrial environments. The unit is suitable for continuous operation under industrial workloads. Compact design allows integration into space constrained systems. Maintenance access is simplified for cleaning and inspection. Energy efficiency is enhanced through optimized flow channels and surface area. The exchanger performs reliably under varying flow rates and thermal loads. Noise and vibration are minimized for industrial settings. Custom configurations are available based on fluid type, capacity, and application requirements.

Cheque,NEFT And RTGS

Key Attributes

Industry-specific Attributes

- Exchanger Type Aluminum heat exchanger

- Material Lightweight corrosion resistant aluminum

- Cooling Medium Water, oil, or process fluid

- Operational Duty Continuous industrial use

- Thermal Efficiency Optimized heat transfer

- Energy Efficiency Reduced operational costs

- Installation Scope Compact and space saving

Other Attributes

- Maintenance Focus Easy cleaning and inspection

- Flow Capacity Customizable based on process requirements

- Integration Capability Industrial process fluid circuits

- Temperature Control Stable and precise

- Noise Level Low vibration and operational sound

- Customization Scope Fluid type, flow rate, and capacity

- Durability Level Long term industrial performance

ALU Heat Exchangers are engineered using high quality aluminum for industrial thermal transfer applications. The lightweight construction reduces installation weight without compromising structural integrity. The design provides efficient heat transfer for process fluids and cooling media. Corrosion resistant aluminum ensures long-term durability in various industrial environments. The unit is suitable for continuous operation under industrial workloads. Compact design allows integration into space constrained systems. Maintenance access is simplified for cleaning and inspection. Energy efficiency is enhanced through optimized flow channels and surface area. The exchanger performs reliably under varying flow rates and thermal loads. Noise and vibration are minimized for industrial settings. Custom configurations are available based on fluid type, capacity, and application requirements.

Cheque,NEFT And RTGS

Key Attributes

Industry-specific Attributes

- Exchanger Type Aluminum heat exchanger

- Material Lightweight corrosion resistant aluminum

- Cooling Medium Water, oil, or process fluid

- Operational Duty Continuous industrial use

- Thermal Efficiency Optimized heat transfer

- Energy Efficiency Reduced operational costs

- Installation Scope Compact and space saving

Other Attributes

- Maintenance Focus Easy cleaning and inspection

- Flow Capacity Customizable based on process requirements

- Integration Capability Industrial process fluid circuits

- Temperature Control Stable and precise

- Noise Level Low vibration and operational sound

- Customization Scope Fluid type, flow rate, and capacity

- Durability Level Long term industrial performance

SS Tube Heat Exchangers are engineered using high quality stainless steel for superior corrosion resistance. The tube design provides efficient heat transfer between hot and cold fluids in industrial processes. Heavy duty construction ensures long term durability and continuous operation. The system supports precise temperature control across varying flow rates. Compact design allows integration into existing piping networks and industrial systems. Energy efficient operation reduces operational costs while maintaining cooling performance. Maintenance is simplified with accessible tube assemblies for inspection and cleaning. Noise and vibration are minimized through optimized structural design. The exchanger is suitable for a wide range of fluids including water, chemicals, and process liquids. The unit ensures stable operation under varying industrial loads. Custom tube configurations are available to meet specific thermal and process requirements.

Cheque,NEFT And RTGS

Key Attributes

Industry-specific Attributes

- Exchanger Type Stainless steel tube heat exchanger

- Material High grade stainless steel

- Cooling Medium Water, chemicals, or process fluids

- Operational Duty Continuous industrial use

- Corrosion Resistance High durability in aggressive fluids

- Thermal Efficiency Optimized tube heat transfer

- Energy Efficiency Low operational cost design

- Installation Type Skid or floor mounted

Other Attributes

- Maintenance Focus Easy tube inspection and cleaning

- Flow Capacity Customizable to process requirements

- Integration Capability Compatible with industrial piping

- Temperature Control Stable and precise process cooling

- Noise Level Low operational sound

- Customization Scope Tube size, count, and configuration

- End User Segment Industrial process cooling operators

Boiler Heat Exchangers are engineered to recover thermal energy from high temperature boiler flue gases or process streams. The system transfers heat to water or other working fluids, improving overall energy efficiency. Heavy duty construction ensures reliable performance under high temperature and pressure conditions. The exchangers support continuous industrial operation while maintaining stable thermal output. Corrosion resistant materials enhance durability and lifespan. Maintenance access is provided for easy cleaning and inspection. The system integrates with boilers, steam systems, and process piping networks. Energy recovered can be reused for heating, preheating, or power generation applications. Noise and vibration are minimized for industrial environments. The exchangers are suitable for chemical, petrochemical, and food processing industries. Custom designs are available to match specific temperature, flow, and energy recovery requirements.

Cheque,NEFT And RTGS

Key Attributes

Industry-specific Attributes

- Exchanger Type Boiler heat exchanger

- Material High temperature resistant metals

- Cooling Medium Water, steam, or process fluid

- Operational Duty Continuous industrial operation

- Thermal Efficiency Optimized energy recovery

- Energy Savings Reduces fuel and operational costs

- Installation Type Inline with boiler or process stream

- Maintenance Focus Easy access for cleaning and inspection

Other Attributes

- Flow Capacity Customizable for process requirements

- Temperature Range High temperature flue gases and fluids

- Corrosion Resistance Enhanced durability

- Integration Capability Boiler and process piping compatible

- Noise Level Low operational sound

- Customization Scope Temperature, flow, and design specific

- End User Segment Industrial energy recovery and process operators

U Tube Heat Exchangers are engineered for industrial applications where temperature fluctuations are frequent. The U shaped tube bundle allows natural thermal expansion without mechanical stress. This design improves operational safety and equipment life. The exchanger delivers efficient heat transfer between hot and cold process fluids. Heavy duty construction supports demanding industrial environments. The system performs reliably under variable pressure and temperature conditions. Maintenance is simplified due to the removable tube bundle design. Compact layout enables easy installation in existing process lines. Energy efficiency is maintained through optimized tube surface area. Noise and vibration are minimized during operation. Custom designs are available based on process temperature, pressure, and flow requirements.

Cheque,NEFT And RTGS

Key Attributes

Industry-specific Attributes

- Exchanger Type U tube heat exchanger

- Tube Design U shaped configuration

- Thermal Expansion Handling Built in flexibility

- Operational Duty Continuous industrial operation

- Temperature Suitability High temperature processes

- Pressure Capability Industrial process rated

- Maintenance Method Removable tube bundle

- Heat Transfer Method Tube side fluid exchange

Other Attributes

- Installation Orientation Horizontal or vertical

- Integration Capability Industrial piping networks

- Material Options Carbon steel or stainless steel

- Energy Efficiency Optimized thermal performance

- Noise Level Low operational sound

- Customization Scope Temperature and pressure specific

- End User Segment Industrial process heat transfer users

Stainless Steel Heat Exchangers are engineered for hygienic heating and cooling in industrial processes. High grade stainless steel construction ensures corrosion resistance and easy cleaning. The design supports sanitary operation for sensitive applications. Efficient heat transfer enables precise temperature control for both heating and cooling. The unit operates reliably under continuous industrial conditions. Smooth internal surfaces reduce contamination risk and product buildup. Compact construction allows easy integration into process lines. Maintenance access is designed for thorough cleaning and inspection. Energy efficiency is optimized for industrial operation. Noise and vibration are minimized for stable performance. Custom configurations are available to meet specific hygiene, temperature, and process requirements.

Cheque,NEFT And RTGS

Key Attributes

Industry-specific Attributes

- Exchanger Type Hygienic stainless steel heat exchanger

- Material Food grade stainless steel

- Process Function Heating and cooling

- Hygiene Standard Sanitary process compatible

- Operational Duty Continuous industrial use

- Surface Finish Smooth and cleanable

- Corrosion Resistance High durability

- Thermal Efficiency Optimized heat transfer

Other Attributes

- Installation Style Inline process mounting

- Maintenance Focus Easy cleaning and inspection

- Integration Capability Hygienic piping systems

- Noise Level Low operational sound

- Customization Scope Temperature and hygiene specific

- Reliability Level Long term hygienic performance

- End User Segment Sanitary process industry operators

Titanium Tube Heat Exchangers are engineered for use in highly corrosive environments such as marine and chemical processes. Titanium tube construction offers exceptional resistance to seawater, chlorides, and harsh chemicals. The exchanger delivers efficient heat transfer while maintaining long service life. Heavy duty design supports continuous operation in demanding conditions. The system ensures stable temperature control for critical processes. Maintenance requirements are reduced due to corrosion resistant materials. Compact configuration allows integration into marine vessels and industrial plants. Performance remains consistent under varying flow and temperature conditions. Noise and vibration are minimized through robust structural design. The exchanger is suitable for offshore, coastal, and chemical processing applications. Custom configurations are available based on flow rate, temperature, and process requirements.

Cheque,NEFT And RTGS

Key Attributes

Industry-specific Attributes

- Exchanger Type Titanium tube heat exchanger

- Tube Material Pure or alloyed titanium

- Application Environment Marine and chemical processes

- Corrosion Resistance Excellent in seawater and chemicals

- Operational Duty Continuous industrial use

- Heat Transfer Efficiency Optimized tube design

- Installation Style Skid or marine mounted

- Maintenance Focus Minimal due to material properties

Other Attributes

- Flow Capacity Customizable for process needs

- Temperature Control Stable and reliable

- Pressure Handling Industrial marine rated

- Integration Capability Marine and process piping compatible

- Noise Level Low operational sound

- Customization Scope Tube size, count, and layout

- End User Segment Marine and chemical process operators

Finned Tube Heat Exchangers are engineered to maximize heat transfer efficiency using extended surface fins. The finned tubes increase the effective heat exchange area without increasing system size. This design improves thermal performance in air and gas based applications. The exchanger supports reliable heating and cooling for industrial processes. Robust construction ensures long service life under continuous operation. The system handles variable temperature conditions with stable performance. Compact layout allows easy integration into existing systems. Maintenance is simplified due to accessible fin and tube arrangement. Energy efficiency is enhanced by improved heat dissipation. Noise and vibration are minimized during operation. Custom designs are available to meet specific industrial heat transfer requirements.

Cheque,NEFT And RTGS

Key Attributes

Industry-specific Attributes

- Exchanger Type Finned tube heat exchanger

- Heat Transfer Method Extended surface fins

- Primary Medium Air or gas

- Operational Duty Continuous industrial use

- Thermal Efficiency Enhanced by finned design

- Installation Style Horizontal or vertical mounting

- Maintenance Access Easy fin cleaning

- Integration Capability HVAC and process systems

Other Attributes

- Pressure Handling Industrial rated operation

- Temperature Stability Consistent heat transfer

- Noise Level Low operational sound

- Customization Scope Fin pitch and tube layout

- Reliability Level Long term performance

- Energy Usage Optimized thermal exchange

- End User Segment Industrial thermal management users

Air Cooled Heat Exchangers are designed to dissipate process heat using surrounding air. The system uses finned tubes and forced or induced airflow for effective cooling. This design reduces dependence on water based cooling systems. It supports stable temperature control in industrial operations. Heavy duty construction ensures reliable outdoor performance. The unit operates efficiently across varying ambient conditions. Maintenance is simplified due to dry cooling operation. Compact modular design allows flexible installation. Energy consumption is optimized through efficient airflow management. Noise levels are controlled for industrial environments. Custom configurations are available to match process heat load and site conditions.

Cheque,NEFT And RTGS

Key Attributes

Industry-specific Attributes

- Exchanger Type Air cooled heat exchanger

- Cooling Medium Ambient air

- Water Requirement No water usage

- Operational Duty Continuous outdoor operation

- Heat Dissipation Style Dry air cooling

- Installation Area Open or rooftop mounting

- Structural Design Weather resistant frame

- Maintenance Requirement Minimal compared to water systems

Other Attributes

- Energy Consumption Fan driven airflow

- Temperature Control Ambient dependent cooling

- Noise Level Industrial standard control

- Customization Scope Fan size and fin density

- Reliability Level Long term outdoor performance

- Environmental Benefit Water conservation

- End User Segment Water limited industrial facilities