Key Attributes

Industry-specific Attributes

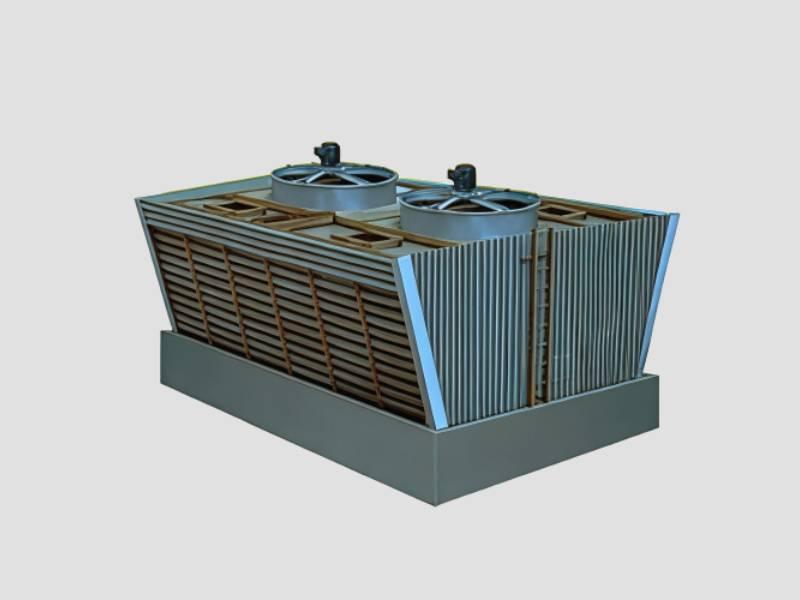

- Airflow Design Induced draft enhanced airflow

- Fan Position Top mounted configuration

- Structural Material Timber construction

- Cooling Objective Industrial process heat removal

- Thermal Efficiency Improved airflow performance

- Energy Usage Optimized fan power consumption

- Operational Stability Continuous duty operation

- Vibration Control Timber based damping

Other Attributes

- Air Discharge Top discharge arrangement

- Maintenance Access Organized internal layout

- Noise Control Reduced operational noise

- Installation Environment Outdoor industrial use

- Customization Level Capacity and layout adjustable

- System Reliability Long term industrial performance

- End User Segment Industrial process cooling operators

_209681.jpg)

_209681.jpg)

_209681.jpg)